Blog

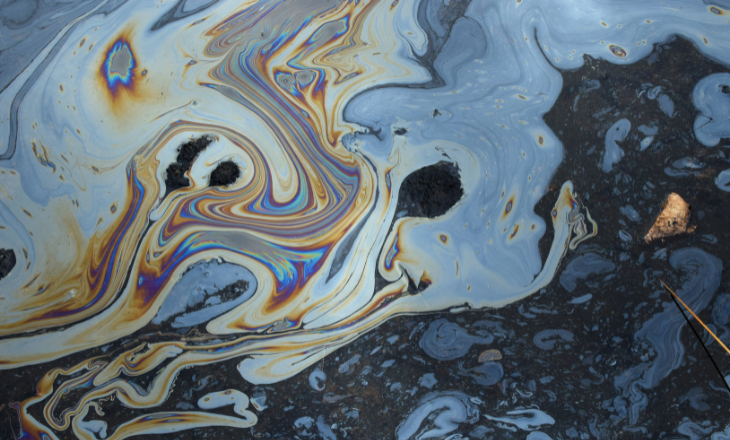

Do You Have the Right Spill Kit Ready?

Having the right tools for the job goes without saying, but do you have the right spill kits to hand?

Spill kits are essential to protect people, infrastructure, stock and effectively clean up a hazardous mess, but the wrong kit can be dangerous, and could do more harm than good.

Accumax is committed to reducing risk in your workplace and has compiled a checklist to help you make sure you have the right spill kits on hand.

Match the Kit to the Hazard

To effectively clean up and keep people safe, the kit type must be compatible with all chemicals and liquids on-site. A mismatch will not only fail to clean up, but risk harmful chemical reactions.

There are usually three common types of kits:

- oils, coolants, solvents and water

- oil based liquids only

- corrosives or unknown liquids

You may need one, two or all types on-site.

Volume and Absorbency

Next, consider the volume of each liquid you have on site. Measure based on worst-case scenario, so you know you are prepared.

This stock will need reassessing regularly and after an incident to ensure it’s at full capacity and you don’t get caught out. Reorder to refill when necessary.

PPE

Don’t assume the kit includes the right PPE, double check the fabric and equipment in each kit will protect your staff against a worst-case scenario of multiple spills at the one time.

Drain Protection

Double check the drain protection in the kits will firstly; fit your facility’s drains and secondly; is compatible with all the chemicals used on-site in the event of multiple spills.

Expert Advice

There are a wide variety of spill kits available, if you need help selecting the right one, have any questions or would like to know more about OHS provisions, contact us today or take a look at our range of spill kits.